Thermal Energy Storage (TES)

Concept

Thermal Energy Storage capabilities on the cheaper off-peak tariff offered by the electric utility company. The system produces cooling energy at night when the electricity tariff is low.

During the day, when the air-conditioning demand is high, the stored cooling energy is released by circulating chilled water through the storage system and onto the buildings. Only a limited amount of chiller capacity needs to operate during this period.

By adopting this concept, the plant consumes less electricity during the day, when electricity tariff is high. This leads to significant savings in operating costs.

As the electrical power demand for this plant is also low during the day, further cost saving is achieved through reduced maximum (MD) charges.

TES System Types

Broadly, TES system can be categorized into two types:

- Ice storage

- Chilled water storage

Each system has its own advantages and disadvantages, depending on the specific application.

Benefits

Technical:

- Reduction of the installed chiller capacity

- Reduction of short cycles

- Increased system efficiency and reliability

- Simplified maintenance

- Flexible system

Environmental:

- Limited use of ozone-depleting refrigerants

- Reduced noise pollution

Financial:

- Shifting of electricity consumption from day to night

- Saving on the maximum demand charge

- Reduced average cost of air-conditioning

How TES Technology Saves Energy Costs

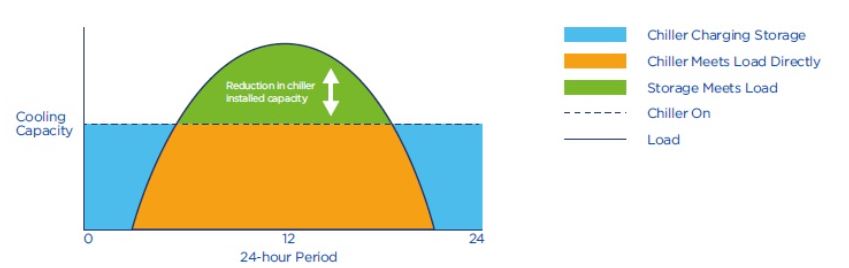

In a typical TES application, the chiller capacity is less than the design air-conditioning demand. The chiller meets part of the on-peak cooling load and the storage meets the rest.

The chiller would run at full capacity for most of the time. When the load is less than the chiller output, the excess charges storage. When the load exceeds chiller capacity, the additional requirement is discharged from storage.

The diagram below clearly shows that the plant installed chiller capacity can be greatly reduced when compared to the conventional system.

Since the chiller is operated at full capacity most of the time, it is now better utilised and able to perform at high efficiencies.

The TES plant load is also more levelled compared to the conventional plant where its load must follow the cooling load very closely. The conventional system would be charged higher for its high maximum electrical demand.